Transforming Industrial Diagnostics: FluIDect’s Microfluidic Technology Breakthrough

In the rapidly evolving field of microfluidics, a groundbreaking innovation is set to transform the landscape of microbial detection and quality control in industrial settings. FluIDect, a pioneering entity in the biotechnology space, is at the forefront of this transformation, leveraging the advanced capabilities of microfluidic technology to introduce a novel sensor system designed for continuous, real-time monitoring of liquid products for specific microbial presence.

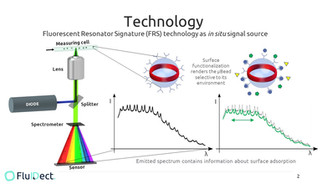

The Technology Behind FluIDect's Innovation

At the heart of FluIDect's innovation lies the Fluorescent Resonator Signature (FRS) technology, a sophisticated approach that employs fluorescent, surface functionalized polymer microbeads. These microbeads are engineered to specifically bind to target microbes via antibody binding while floating freely in the analyte. When these microbeads traverse through a measuring channel, the organic dye embedded within the polymer is energised by a laser, causing the beads to emit a characteristic wavelength glow. This phenomenon, driven by Whispering Gallery Modes formed inside the beads due to their fluorescent radiation, enables the optical identification of the amount bound microbes or proteins.

This technology not only represents a significant leap in microbial detection but also facilitates a complete overhaul of quality control processes in industries such as pharmaceuticals, food and beverage, and water treatment. By enabling continuous monitoring, FluIDect's system promises to enhance product safety, reduce contamination risks, and optimize manufacturing processes.

Impact and Applications of FluIDect microfluidic microbial detection

FluIDect's sensor technology is poised to have a profound impact on various sectors by offering an unprecedented level of precision and efficiency in microbial detection. For the pharmaceutical industry, this means ensuring the sterility and safety of products with much higher confidence. In the food and beverage sector, it translates into the ability to continuously monitor production lines for microbial contamination, drastically reducing the risk of foodborne illnesses. Additionally, water treatment facilities can benefit from real-time monitoring of water quality, ensuring safe drinking water and compliance with regulatory standards.

Collaboration with the MIH family

To bring this innovative technology to market, FluIDect has joined forces with the #MIHfamily. This collaboration underscores a shared commitment to advancing microfluidic technologies and their applications in real-world settings.

MIH provides project management and communication support, ensuring the seamless coordination of all project activities.

Micronit b.v. contributes its extensive expertise in the design and manufacturing of microfluidic chips, playing a crucial role in the development and optimization of the sensor system.

Bionic surface technologies GmbH offers specialized knowledge in fluidic simulation, enhancing the efficiency and effectiveness of the microfluidic system through optimized flow behaviour.

This collaboration is instrumental in transforming FluIDect's prototype into a scalable, commercially viable product. By leveraging the collective expertise and resources of the MIH family, FluIDect is well-positioned to navigate the complexities of product development, regulatory approval, and market entry.

Comments